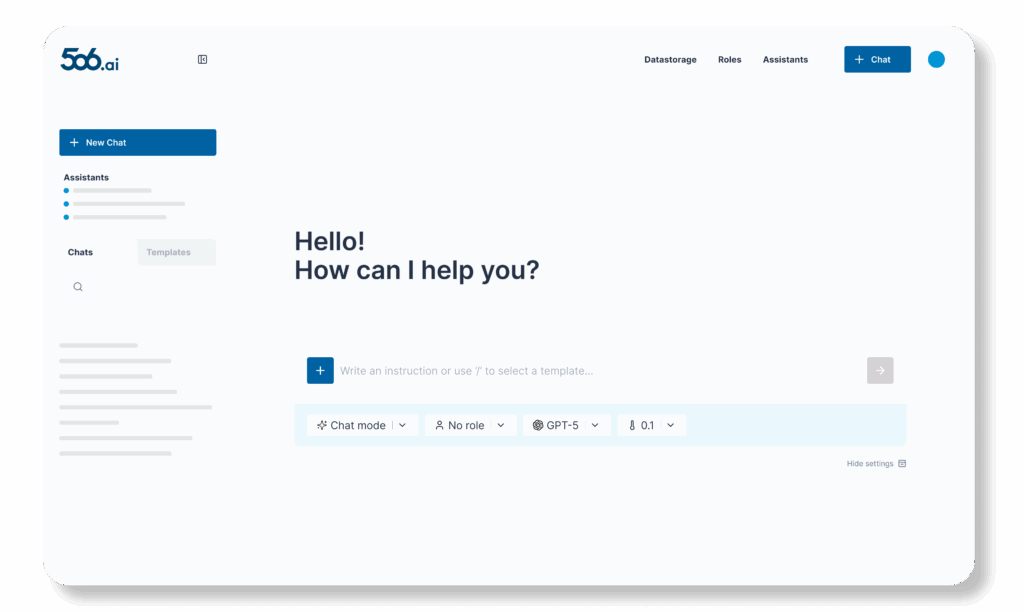

The 506.ai platform for

mechanical engineering & industry

With our AI platform, you can centralize knowledge, automatically structure shift logs, and accelerate root cause analyses – for stable processes, higher productivity, and seamless integration into your existing system landscape.

More efficient production, fewer downtimes & assured quality

Production companies today face high pressure due to rising costs, an increasing variety of products, a shortage of skilled workers, and strict documentation requirements. At the same time, processes must become more efficient and robust – without placing additional burdens on employees.

The 506.ai platform supports you exactly where it counts: It makes scattered knowledge usable, improves shift handovers, accelerates root cause analyses, and provides more transparency in daily production.

Your challenges – Our solution

Distributed knowledge about maintenance and SOPs

Important instructions, maintenance guidelines, or deviation logs are often scattered in PDFs, Excel files, or on paper. With 506.ai, they become centrally available, searchable, and accessible at any time.

➡ Faster onboarding, fewer errors, higher efficiency.

Data chaos and quality problems during shift handovers

Protocols, Excel lists, and emails are neither standardized nor easily accessible. Our AI automatically condenses the information into a structured overview: What went well? Where were there problems? What is open?

➡ Smooth handovers, fewer queries, consistent quality.

Little time for root cause analyses

Although production stops and quality deviations are documented, they are rarely analyzed in depth. 506.ai identifies patterns in fault messages, tickets, and logs, providing relevant clues to recurring causes.

➡ Faster problem solving, more sustainable improvements, fewer escalations.

What 506.ai does for you

- Secure & Utilize Knowledge: Maintenance guidelines, deviation logs, & training documents are centrally searchable and available exactly when needed.

- Structured Shift Logs: Automatic summaries ensure clear handovers without loss of information.

- Accelerated Root Cause Analyses: Recognize patterns and correlations to sustainably resolve recurring problems.

- Efficiency in everyday work: Less search effort, fewer errors, and higher production quality.

Impact from pilot projects

- 40% less time spent on shift handovers

- 60% faster response time for recurring quality problems

- 100% traceable root cause clarification for production stops

Are you ready to future-proof your production?

With the 506.ai platform, you increase efficiency, secure knowledge, and improve quality – without additional burden for your employees.